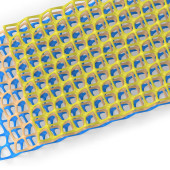

Plastics Perspex Acrylic

We can laser cut a wide range of plastics but we mostly use Perspex (particularly acrylic), as this cuts really well with a laser. However there are some plastics not suitable for laser cutting as the fumes can be toxic. mostly PVC and vinyl

most plastics, Perspex, acrylic, we have in stock and some can be made to special order. If you can’t find the specific material you require please let us know and we will try and help to the best of our experience and knowledge.

Acrylic was one of the first materials to be laser cut. It’s unique in that it’s the only material that completely vaporises when cut – it doesn’t melt and drip, it just disappears!

There is a vast range of colours available (normally in 1mm & 10mm thick) but not all colours shown in the supplier brochures are always available. Don’t forget acrylic is an excellent material for laser engraving.

Acrylic perspex plastic

- Polished cutting edges even in filigree contours without re-work

- No force impact on the material – therefor no mechanical stress of the material

- Highest precision and great advantages in filigree cuttings, even the smallest lot sizes can be produced economically

- Processing of pre-mounted multilayer function panels

- Chipless laser cutting and engraving of plastics

Engineering Plastics

Engineering plastics covers a variety of types such as Nylon, Acetal, PTFE, Tufnol, UHMWPE, HDPE ABS, HIPS, Lexan, Polypropylene ,RG1000

as well as covering many more. In particular when compared to metal, engineering plastics provide:

- High strength to weight ratio

- Good corrosion resistance

- Good electrical and thermal properties

- Low coefficient of friction

- Excellent resistance to wear

- Self lubricating properties

- Noise reduction

- Cost effectiveness

- Wide operating temperature range

These properties may be further enhanced by a range of fillers or modified grades. We can cut up to 10mm thickness in engineering plastics and we keep in stocks various types of thickness and colours.